Lean and Six Sigma are among the most powerful and popular business process improvement methodologies which are being rapidly deployed by a variety of service and manufacturing organizations across the world. The guide below investigates the relation of Lean and Six Sigma with the environment, offering advice on how environmental conservation professionals can use the principles of Lean Six Sigma in order to obtain improved operational and environmental outcomes.

Defining Lean and Six Sigma

Normally referred to as Lean manufacturing, the lean methodology refers to business methods and principles which were initially developed as the Toyota Production system by the Japanese car manufacturer. The lean methodology focuses on systematically identifying and eliminating waste or non-value adding activities that consume capital or resource time.

At many organizations, Six Sigma refers to a measure of process and production qualities that strive to achieve near perfection. It is a data-driven, disciplined approach to production that aims to eliminate process defects in a variety of fields that range from transactions and manufacture to service and product provision.

The Importance of Connecting Lean Six Sigma to Corporate Environmental Efforts

Both Lean and Six Sigma are heavily reliant on a culture of continuous improvement which is perfectly aligned with the environmental goals of sustainability and prevention of pollution. There are a number of compelling reasons why Lean Six Sigma methodologies should form a major part of corporate environmental improvement and sustainability efforts. Some of these are:

- Quick and Dramatic Outcomes: One thing that Lean does is produce quick results. This is because many lean events last only 2-5 days and, in this period, teams will enjoy dramatic reductions in cost and lead times, as well as corresponding improvements in customer satisfaction and product quality. Use of lean methodologies in resolving environmental issues can offer impressive and dramatic results as well.

- Continual Improvement Culture: Lean Six Sigma tools can be used to engage all employees at each level of the organization in efforts to identify and eliminate waste from processes. If environmental waste is included in these improvement efforts, Lean Six Sigma becomes one of the most powerful ways to develop a culture of continuous improvement and sustainability. Sustainability and environmental stewardship is becoming more valued in the new generation of workers.

- Avoiding Pitfalls: Integration of Lean Six Sigma in environmental improvement efforts is one way to minimize an organization’s environmental impact and risks, while navigating regulatory issues and avoiding penalties for non-compliance.

How Lean Six Sigma Implementation Provides Environmental Improvement Results

There is a whole host of ways through which environmental protection professionals and organizations can leverage the power of Lean Six Sigma to improve results. Lean approaches to the environment are strategies that incorporate environmental improvement efforts with the principles of the methodology. Some examples of such implementations include:

- Connecting of Lean Six Sigma and Environmental Improvement Efforts at Facilities: Safety and environmental health professionals can offer support for operations-driven Lean Six Sigma implementations, helping them to expand their scope, expose hidden sources of waste, reduce time to implement when permits and legal paperwork might be involved, and improve operational and environmental results.

- Delivery of Lean Six Sigma and Environmental Technical Assistance: By partnering with Lean Six Sigma experts, environmental technical assistance personnel can deliver environmental protection services more effectively, and better quantify those results for regulatory agencies.

- Using Lean to Boost Effectiveness Of Environmental Programs: The visual controls used in lean and other concepts that form part of the methodology can boost the effectiveness of environmental compliance efforts, and reduce the chance of mistakes, near misses and environmental disasters. In addition, environmental agencies can use lean to help reduce waste produced by various business processes. The State of Iowa launched a lean program in order to speed up the time it took to issue new air permits, in order to allow businesses to expand and grow.

It is essential that environmental professionals understand how to interface with Lean Six Sigma experts so as to develop successful and effective partnerships. Lean Six Sigma experts can also learn from environmental consultants and professionals, to better identify opportunities and capture cost benefits within the work processes they improve.

Did you know that environmental benefits can be achieved by accident?

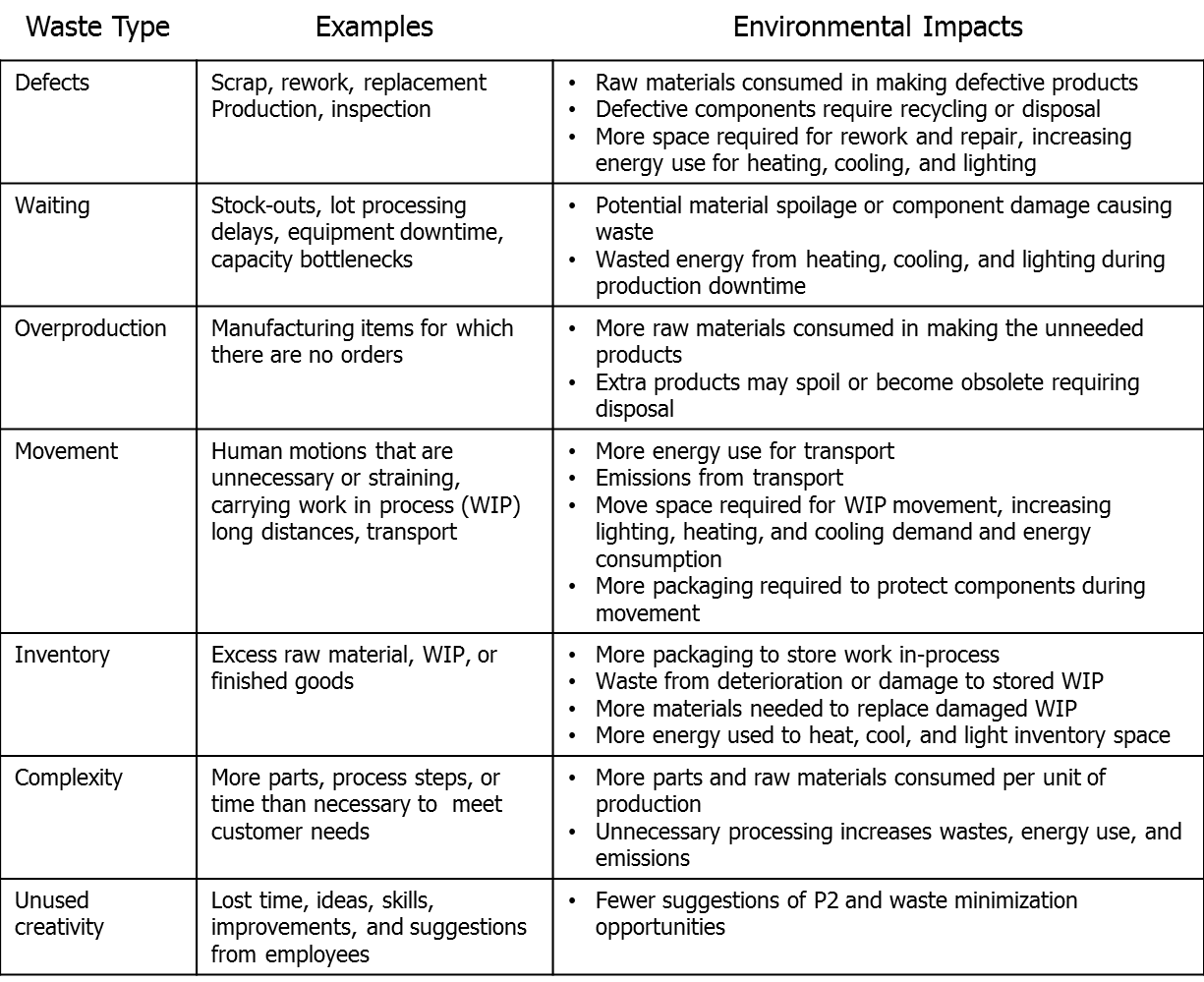

The US EPA published a table showing the connection between reducing the lean wastes and the impact on the environment

By applying Lean and Six Sigma to their organization, companies can reduce their environmental impact without even trying. They probably already have, and not realized it, or captured the benefits. Learn more about Lean and the EPA at their website.

Conclusion

There is no single cookie-cutter approach to integrating lean efforts and the environment the only way to succeed is by trying it out. As Lean and Six Sigma implementations continue to increase alongside the growing realization among organizations of the importance of environmental sustainability in their operations, there is an exciting opportunity to use these methodologies to reduce waste and improve the environment.

If you like this topic, check out the website LeanSixSigmaEnvironment.org for more examples and free online training.

No responses / comments so far.