Earlier, we discussed one application of Queueing Theory in warehousing using this reference on Little’s Law. You can also view all 40+ articles on Queueing Theory.

Now, let’s discuss part 2 of the queueing theory series. Let’s begin with Little’s Law, formalized as:

L = λW

In that post, I stated that a goal in a process is to make the inputs flow as fast as possible through a system in order to produce an output. As an example, I shared an example from Amazon.com. Specifically, I stated that in a click-to-ship system, we want product to move with velocity. Is that always possible in a system and can that be a realistic goal?

In reality, customer orders arrive sporadically, stochastically, and unpredictably. Imagine a supply chain consisting of a network of ~30 U.S. and Overseas distribution centers (I’m talking about Amazon.com here). These distribution centers are multi-echelon, which means that products are stored in both “Prime” locations and in “Reserve” locations. In these types of systems, the products in “Reserve” locations replenish the “Prime” stock, and Amazon’s outside suppliers replenish products in the “Reserve” locations. In that supply chain, often times, orders create spikes in demand that disrupts manufacturing schedules, cause overtime, decimates raw material supplies or current inventory levels, and wipes out finished goods buffers.

Demand also creates service problems for customers who wouldn’t be able to get the products they wanted because a spike in demand had consumed finished goods stocks or Reserve inventory. The challenge is to extend the smooth flow of materials and information upstream, beyond the plant-level, but all the way through the supply chain including to the distribution centers in the U.S. and Overseas and outside suppliers. The solution is to smooth out the peaks and valleys in the demand coming from the distribution centers by leveling the type and quantity of production and filling orders from carefully controlled finished goods markets or on-hand inventory.

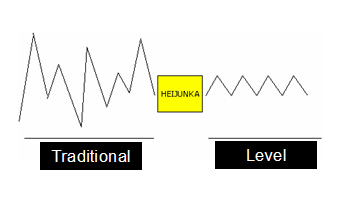

Leveling, or Demand Production Leveling, is technically known as Heijunka. This word comes from the Toyota Production System and is a Lean Manufacturing term. The goal of heijunka is to create balance by leveling demand the flow of production in a system. Graphically, you can imagine Heijunka to look like the following:

Amazon.com has a pull system in place — a very, very good one, though it’s not completely pull. Creating pull is a prerequisite to having flow and demand production leveling (more on pull in another post). In other words, information systems must allow for Amazon’s suppliers to know the inventory levels of the Amazon.com Reserve stock. So, information flow and product flow are key in these situations: when the MIN level of Reserve Inventory is reached, the information system should pull from the supplier the right amount of inventory to bring the Reserve levels back to planned levels.

Back to heijunka. At Amazon.com, there is a buffer in place that stages all orders. This means that when an order is made, orders sit in a queue — a virtual queue before that order is dropped or assigned to an fulfillment center. This buffer or waiting queue acts as a load leveler; else, orders would be coming into a fulfillment center at the rate of demand, which is characterized by peaks and valleys. But, the goal is to level demand production, since we can’t entirely control demand. In other words, velocity is still key, but we must have balance in the system first in order to pull an order through with velocity.

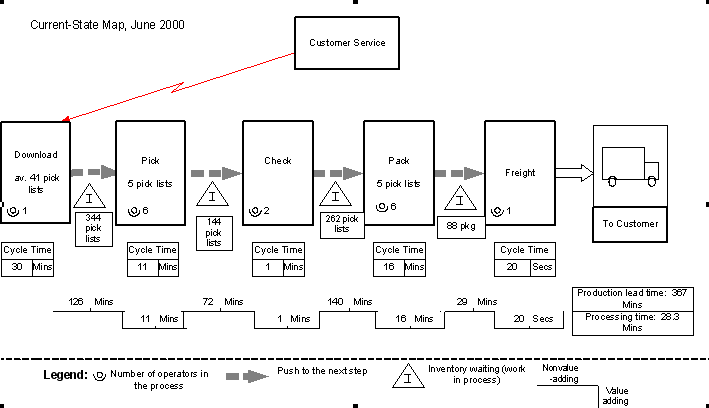

Another example of Heijunka is from Medtronic, a medical device manufacturer. They dealt with the same problems I mention above — unforseen demand and on-the-whim reactions to that demand which created imbalance in their system. Their approach was to create a Value-stream map, which shows process, time, and waste dimensions in a system. Below is their current state map of their distribution process:

Mapping revealed that the daily operation required 16 people and that an order took 367 minutes to progress from initial download to actual shipping. During the 367 minutes of lead time, the order was actually being worked on for just 28.3 minutes. Much of the rest of the time, it was waiting for the next processing step to occur, as represented by the inventory triangles between steps. The logistics team calculated the lead time represented by the inventory triangles. The triangle between pick and the next step, check. It showed that the logistics team found 144 lists or orders waiting to be checked. In the data box for check, the team recorded its observation that the cycle time for an operator to check an order was one minute. Since there were two people checking orders, it would take them 72 minutes to process the 144 lists or orders in the queue.

What is amazing about what this team discovered is that only 7% of the time, the product was undergoing a value-adding stem. The rest of the time, was waste. Is there a way to make this process leaner, with less waste?

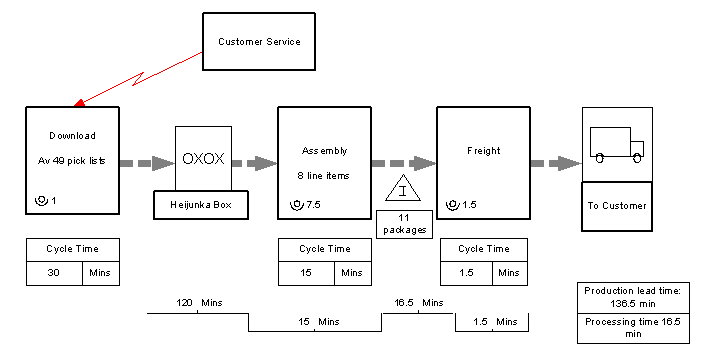

The next action for the logistics team was to map out and implement a leaner future-state by using the information uncovered during the current-state mapping process. For example, scanning at both the check and pack steps was a duplication of work, an obvious waste that the team wanted to eliminate. The problem was how to make sure the orders weren’t mixed up in the totes. Many of Medtronic’s products were small and had to be put in totes to prevent them from falling through the conveyor. The team then realized that the conveyor was causing the need for double scanning. If orders were picked, placed on a cart instead of a conveyor, and wheeled to a scanning terminal, then the pick, check, and pack steps could be combined into one assembly station. The team made the improvement. The only significant cost was a $3,000 fee to the scanning program vendor for reprogramming.

This new process is much leaner, quicker, supports pull, creates balance, and is much faster than the previous process. Many steps were eliminated and waste was reduced. The outcome? From click-to-ship, the process moves with velocity, and the customer receives his or her product much quicker. Notice the Heijunka box above — this creates the balance and reduces unthoughtful reactions to unpredictable demand.

I disagree with your comment that “the goal” is to level demand. Maybe, but what you described really is “leveling production” (to some extent) by having that queue in the order information flow. This queue also causes a delay, but might not delay the order from getting out to the customer on time.

But still, Toyota doesn’t really have level demand. They level production at the assembly plants through the use of dealer lot inventory. Toyota is leveling “demand” as seen by the factory and they are definitely leveling demand on the suppliers, which has huge benefits.

Does that approach really apply to Amazon? I’d argue that Amazon is more like Dell. Dell has very un-level demand. And, because they don’t have dealer lots, Dell can’t level production. They have to allow capacity to fluctuate with demand. If capacity fluctuates perfectly with demand, then cycle time would be constant (which is what Dell quotes, a constant 5-day lead time) — that’s another example of Little’s Law.

Dell does have a very unique opportunity to truly level and shape demand through sales tactics… but they’ve barely scratched the surface on doing that. Dell has a lot of wasted capacity early each quarter because of their un-level sales and un-level production. This creates a lot of stress on suppliers when they have to ship a ton of parts to Dell at the end of the quarter. One thing that helps level things for the suppliers, actually, is that Dell’s end-of-quarter month is one month later than HP’s.

So anyway, when talking about leveling, be careful in the distinction of leveling demand and leveling production. Don’t level production in a way that hurts the customer. If Dell were to take a hard line and say “it’s cheaper and more efficient for us to level production…. so you have to wait 60 days for a PC” they would go out of business. The goal is making the customer happy and making money. Don’t put leveling ahead of that goal.

Another thing that impacts the load on suppliers is how often you order. If Amazon ordered weekly from a vendor, that’s going to cause less of a burden than ordering 4x the amount once a month. Oftentimes, though, companies “optimize” shipping cost by ordering less often, sometimes ignoring the cost of holding the extra inventory and always ignoring the cost to the supplier.

If Amazon had true pull from their suppliers, they could shrink the “reserve inventory” and replenish right to the “prime inventory?” Dell might want you to think they do that, but their “reserve inventory” is cleverly held offsite by a vendor. Dell only has the prime inventory (about 4 hours worth) in house.

Anyway, Peter, I don’t mean to dump all over your post. Good stuff and great topics to discuss. Please take my comments in the spirit of continuous improvement. If you think I’m off base, let’s debate it constructively here or on my blog.

That makes sense what you’re saying. I would think that amazon would have the power or the pull (pun intended) to get suppliers to change those practices, to help reduce minimum buys, to go away from volume discounts (just provide the price, we’ll give you volume over time), etc.

The idea of amazon not being able to be “lean” depends on your definition of lean. Even without leveled demand/production, if amazon were to focus on the people side of lean, they would have huge opportunities for improvement. I love amazon, I order from them all the time and can only think of one screw up in 9 years of being a customer. But, that said, I’m sure there’s room for improvement…. did they look at the Toyota leadership model or just the lean/TPS tools?

TPS is basically 1) reduce waste and 2) respect people. Most American companies seem to focus only on the first part. It’s a rare company that sets a goal of treating people with respect, valuing their ideas, and challenging them to get better. Most companies view their workers as robots without brains. Getting past that and getting toward continuous improvement, that’s something any company can work on, with the right leadership.

Let’s keep talking! Congrats on getting the blog launched. It’s an interesting mix of topics here!

@Mark,

Thanks for your comments.

Yes, thanks for the correction on leveling production, versus leveling demand.

Eliminating the “reserve” and put everything in “prime” was something that we looked at. But, we determined that it wasn’t entirely possibly to have a Lean factory at Amazon. Lot purchasing to receive the price/quantity breaks was one reason — and this was a policy decision that was difficult to battle. There were other reasons also, but we definitely looked at shrinking the Reserve bins.

We need to talk more. I’ll be sharing some of my experiences here soon on my time at Toyota, Hebron, KY — the auto supply parts distribution center, not the auto making plant.

Pete

Reducing wasteful steps is really more the key lean concept than following “pull” is, in my opinion.

Hi Mark. They tended to look at (1) primarily but they started really looking at (2). I think Amazon does realize that their people hold a vital key to their success. There were several initiatives that were being introduced to help deal with how they should respect people.

I don’t think they gave up on becoming lean though. They obviously can’t do a true pull system but they do try to eliminate the wasteful steps that occur in their process.

Great topic Peter!

T