As I teach the principles of Lean Manufacturing to others, I include games that are both fun and also illustrate the concepts in a way that are memorable and solidifies the concepts more clearly in the student’s mind. There are many games that help better explain the sometimes counter intuitive concepts of Lean. One of those games is the Airplane Game.

The Paper Airplane Game

The paper airplane game is a simple exercise that illustrates in a visible and experiential way the difference between pull systems and push systems. In the videos below, they start with a craft assembly simulation for Round 1, where all 6 workers are used, and one person is the timer. This is an optional part of the simulation. A simpler version is to use two rounds: Mass production (Round 2) and Cellular Assembly (Round 3).

The game goes like this (starting with Round 2):

Participants

- 4 Workers

- 1 Manager

- 1 Material Handler

- 1 Timer

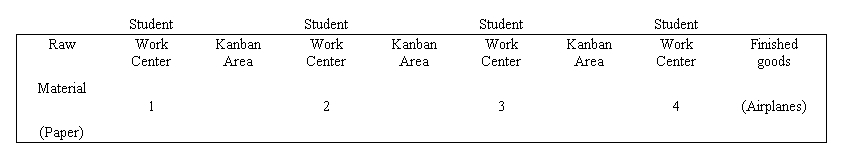

Data Collection

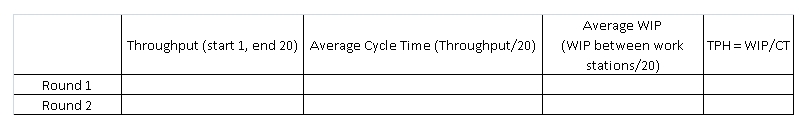

Collect data according to the table below:

Layout

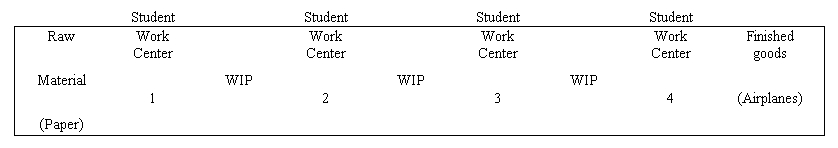

The layout of the assembly line is as follows:

We will use the layout above for both Round 2 and Round 3, but Round 3 will have a slight difference in between workstations.

Paper Airplane Assembly

Planes are to be assembled according to the instructions below:

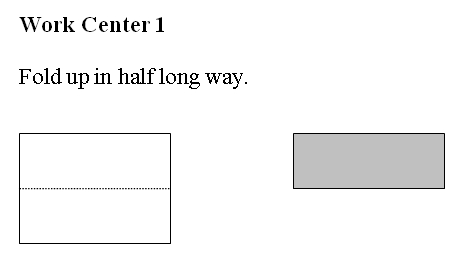

Worker 1:

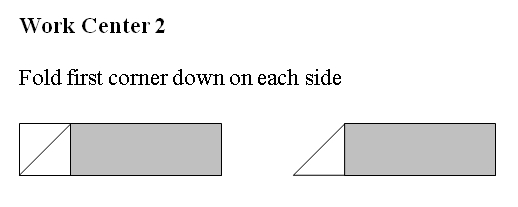

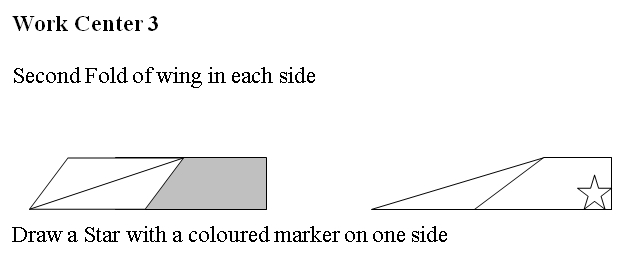

Worker 2:

Worker 2:

Worker 3:

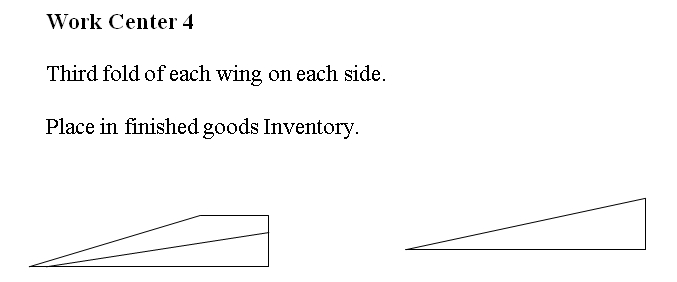

Worker 4:

Round 2

In Round 2, we will illustrate a push system. Watch the 18 minute video example below to see how to facilitate the Paper Airplane Game and help your audience see the difference between Push Production and Pull Production. Reminder that the first part of the video (Round 1) is an optional simulation around craft production.

- Instruct workers to work at a comfortable pace, but there is a bonus for producing finished planes faster rather than slower.

- The quality will be monitored by the QA associate and only he/she can specify quality rejects.

- Goal: complete 20 airplanes at the Finished Goods Station.

Round 3

In Round 3, we will illustrate a pull system. You no longer need the manager and material handler, only the timer.

- In between the work stations, there is a staging area for Work-in-Process (WIP) – a plane that’s partly finished.

- The staging area between the workstations is the outbox from the previous worker and the inbox for the proceeding worker. In other words,

- Worker 1 and Worker 2: Outbox for 1 and Inbox for 2

- Worker 2 and Worker 3: Outbox for 2 and Inbox for 3

- Worker 3 and Worker 4: Outbox for 3 and Inbox for 4

- A worker cannot put unless the staging area is empty.

The Layout for Round 3 looks like the following:

- The Facilitator places 1 unit of WIP in the staging areas between workers. In other words, place 1 airplane halfway folded between Station 1 and Station 2. Do the similar step for the other staging areas.

Discussion Topics

- Where was the bottleneck? How do you know?

- Was there any finger pointing or blaming or cynicism? Why?

- Why was the cycle time of Round 3 “Pull System” Run lower than Round 2 “Push System” Run?

- Inventory – why was there lower inventory build-up in the Pull System than the Push System?

- Is lower WIP necessarily better than higher WIP? Why or why not?

- For Station 1 and Station 2, what was the difference in Idle Time between both Round 2 and Round 3? Is Idle Time necessarily a bad thing we should avoid or eliminate? Why?

- If you managed an assembly line, which method would you choose? Push System or a Pull System? Why?

- Assuming you’ve introduced the concept of Kanban, ask the participants what represented the concept of Kanban in the airplane game.

I’ve found that the discussion is very lively because the participants have experienced and have visually seen the difference between a push versus a pull system. And, when asked which system is better, it is important that the participants learn to defend their position.

In other words, instead of simply accepting “pull is always better than push” – ask them why and ask them to be very specific.

Remember that as you facilitate this exercise, meet your students wherever they are in their lean journey. But most of all, challenge them to think and challenge them to defend their assertions or claims. Doing so eliminates any unproductive discussions of push versus pull and crushes any dogmatic positions of “pull is better than push”, etc.

Paper Airplane Videos

Below are Part 1 and Part 2 showing the Paper Airplane Game Simulation. Part 1 covers Round 1 and Round 2. Part 2 covers Round 3.

[contentblock id=18]

Video Transcript

Welcome to the simulation portion of our Lean basics training. I was taught this paper airplane exercise when I was first learning Lean and I still use it today. I think it’s a great tool. First of all, it’s cheap because all it costs is a couple sheets of paper and maybe some post-it notes. I’ve seen some pretty complex tools out there, some expensive simulation tools and consulting [inaudible 00:00:25] out there. Some of them are excellent, but they cost a fortune.

Welcome to the simulation portion of our Lean basics training. I was taught this paper airplane exercise when I was first learning Lean and I still use it today. I think it’s a great tool. First of all, it’s cheap because all it costs is a couple sheets of paper and maybe some post-it notes. I’ve seen some pretty complex tools out there, some expensive simulation tools and consulting [inaudible 00:00:25] out there. Some of them are excellent, but they cost a fortune.

The second reason why I like this simulation is everything you need to run it is basically in your office already. You need office paper. You need some post-it notes and some stop watches. You get six small chairs together and you can learn basically a lot of the concepts that these more complex simulations have to offer.

The following point I want to make about this simulation is it serves as a bridge for the rest of the simplex improvement lessons. Pay attention and if you have problems following along, go ahead and download the instructions off the site. As I mentioned, the paper airplane simulation is really easy, but let me explain how it runs.

First of all, you need six total volunteers. Four will serve as workers. One will be a manager and one will be a material handler. Each run lasts for five minutes and there’s something called an X plane. That will show us how long it takes to build a plane from start to finish using different scenarios. While we’re running this simulation, we’ll be measuring a lot of things.

First, we’ll be measuring space. You’ll likely be running this in an office environment with tables, so space will be measured in number of tables used. The second thing is work in process. So, how many planes are partially built at the end of five minutes? The next is good parts. How many of those that are fully complete do I, as a customer, consider done correctly?

Next, we have percentage of good. So, those number of done correctly divided by the total number of planes that they considered finished. Next, we have the lead time. That is the X plane that I mentioned earlier. How long did it take to build a plane from start to finish once I inserted the X plane into the system?

Then, we have number of people. As I mentioned earlier, we start off with six, but as the simulation goes on, they learn to decrease that number. Next, there’s time. All these simulations are going to run for five minutes. Last, we have productivity, which is a measure of good parts divided by people divided by time. For the start of this simulation, let’s follow historical flow. If you

recall, everything before Eli Whitney, everything was an art rather than a science, so everything was craft-based. There were no standards, so if you told someone to build you a rifle, they would you a unique rifle. For the start of this simulation, we will tell them to build this plane. In fact, we’ll give them the model. Will they follow the standard? It’s up to them. They usually do a pretty good job mimicking what this is, sort of like craftsmen do, but the standards really aren’t there. In this portion of the exercise, we’re going to use all six workers to be craftsmen for us. Let’s see how this turns out.

Before we get started with the simulation, I’m going to demonstrate how to build this paper airplane. Really simple. The first thing you do is make a fold down the middle. Then, you fold the nosepiece. Then, you fold the wings. Then, you fold the tips, just two folds on each side. That’s it. So, this is the first run of the simulation. I was pretty fortunate to be able to find a group of undergrad students that were interested enough in Lean to volunteer for this exercise. I gave them the same lesson in history you previously saw and let them know that all six of them will be building planes from start to finish, like craftsmen. It still surprises me today to find out that companies out there pride themselves on using the centuries-old way of thinking. They literally have an individual or small team build a large, complex item, an automobile for example, from start to finish. Imagine how much training is needed for these craftsmen. If one of these amazing craftsmen were to win the lottery or retire, replacing them would take years.

Notice how much frustration is involved with learning to build even a simple paper airplane from start to finish and notice how slowly they’re being built. Companies using craft-based manufacturing go as far as to pride themselves on taking months or years to deliver a product that is quote “tailor-suited to you”. For some reason, this niche market they serve seems to not only accept but expect this as a necessary cost of high quality. The reality is craft-based products are generally of lower quality than those that are Lean-produced, or even mass-produced because there are no standards to which they are built. In this simulation and the two to come, I write an X on a blank sheet of paper and start a separate timer to see how long it takes to produce my special order. I allow them to continue to build for five minutes before I stop this portion of the simulation.

So, let’s review the metrics on the first run. We used four tables. There were five in WIP. They only produced four good planes and there were only 15% that were good. The lead time for the X plane was one minute. There were six people producing. The time was five minutes for the total run. Their productivity, which is good parts divided by people divided by time, was 0.133. So, not necessarily a bad start considering craft mentality, but productivity was horrendous. Let’s continue our historical flow and our simulations from mass-production. Then after our history lesson, I mentioned that Henry Ford was the father of mass-production, in that people like to villainize him based off of this. Mass-production is an excellent system and it is a huge step forward from craft-production. One of the downfalls of mass-production is the piece-part metrics. Workers are incentivized to produce a lot. In fact, they drive down the cost of production by producing a lot. So, if two items cost $100 to produce, it cost $50 per item to produce. If that same production cost of $100 were spread over 100 units, then each of those items only cost $1 a piece. Piece-part metrics actually incentivizes workers to produce more than needed, which is over-production, which is a form of waste you’ll learn later.

As a final step in the simulation, we’re going to organize into an assembly line so you’ll see the huge productivity gains we’ll get just from moving from a craft-mentality basis to mass-production and an assembly line. Adam Smith discovered over two centuries ago, there are definite productivity gains to be made by dividing up tasks between workers. In this run, you can see that each worker only had a small component of the total plane to build. There are a couple reasons why this is better than having each worker build a complete plane from start to finish. The first is it speeds up the learning curve. It’ll take a while for me to learn to build this plane from start to finish, but if I only have to learn a fold or two, I can pick it up quickly. But, if the work is passed along an assembly line and each worker is limited to a small set of tasks, like repeatedly tightening a few sets of bolts, then you can train this pretty quickly.

Secondly, there’s that magical productivity gain that Adam Smith discovered from division of labor. When you divide up work, it’s easier for each worker to get faster and faster at his given set of tasks. When you set up these micro-improvements, you’re building the product a lot faster than you were before. I refer to this as magic because the sum of the parts is actually less than the original total amount of time it took to build the plane.

One downside to using mass-production is a high level of stress. The manager continues to push for higher volumes because this drives down the per-unit cost. Each station is working independently and sending work to the next station even though they’re not ready for it. This is called push-production and we’ll talk more about it later on this site.

Also, the material handler adds no value to the process. In a mass-production environment, work in process builds up quickly because there is an incentive to produce more. Work in process in large amounts does nothing but tie up cash and cripples a company. It also makes the material handler appear to be busy when, in reality, his job function as well as that of the manager, add no value to the final product. Because there is so much work in process, my X plane is caught behind a log jam. This is

another downfall of mass-production. It is not designed to quickly respond to rapidly changing customer demand.

So, let’s review our metrics for the second run. In this case, we only used three tables. Work in process, there were 57 units. They produced seven good planes. Seventy percent were good. The lead time for the X plane was three minutes. There were six total people in the system. Again, we ran for five minutes. Productivity, in this case, good parts divided by people divided by time, was 0.233.

Again, the benefits of mass-production over craft-production, they nearly doubled their good planes produced. The work in process was through the roof, 57 compared to 5. You can also see that they had a huge productivity gain from using mass-production. You can see a near 75% productivity gain from the first to the second run.

For our last run of the simulation, we’re going to take Ford’s mass-production system and morph it into Lean-production. We’re going to focus on quality at the source, level-loading, pulling, and pacing. This is what I mean by quality at the source. You can’t inspect quality. It has to be built into the process.

So, this little jig here, make sure that every first fold is correct because we noticed that the majority of the defects were happening early in the process. With these three nails, if you lay the piece of paper on here and you know every single time, you’re getting a perfect fold. This is what I mean by level-loading. You can tell from the second run, that this production line was not very well level-loaded. Worker one only had to do one fold, whereas, worker four had to do four folds. Workers two and three

only had to do two folds a piece.

As a result of the imbalance, you can see that worker one had the least to do. Worker four had the most to do, with four folds. Worker one could out-pace everyone and the majority of the WIP was caused by worker one. As a customer, I need planes every 24 seconds and the way this system is set up right now, they can’t make it because worker four takes about 32 seconds to complete his portion. This is where level-loading comes in. You can see that we divided all the folds pretty evenly across all the operators. You can also tell that they’ll easily be able to meet the customer demand of making a plane every 24 seconds.

For run three, the team decided not to use a material handler and a manager because they were adding no value to the final product. The production line was reconfigured so every was sitting very close to one another. This eliminated the need for the material handler. There were also post-it notes placed between each work station. This was to prevent over-production.

Remember during the last run when there was a staggering 57 pieces of work in process? These post-it notes prevent that. The simple production rule that the team agreed to was to only produce when the post-it note to their immediate right was not covered by a plane that was work in process. Only when the post-it note was exposed by the next operator taking that piece of work in process could the previous worker begin working. This is called pull-production. This is in contrast to push-production you saw during the last run.

This simple control eliminates the need for a manager, as the pace and the amount of production is totally dictated by how often the customer pulls a plane. Notice that with this control in place, the worst case scenario can be three pieces of work in process at any given time. These concepts that Smith, Ford, and Toyota developed don’t have to limited to assembly. If you’re like most companies or hospitals, paperwork is another factor that no one pays attention to. It takes a long time for people working in this area to learn how to process orders or invoices.

Why not set these individuals up in a cell similar to this one? Each worker would process just a component of the order or invoice and pass it along. I’ve personally created numerous cells in office environments for order processing where people didn’t believe a work-cell concept applied. The results were huge gains in productivity and far fewer defects. Notice the slower and more controlled pace the operators are working in. They agreed not to push defects onto the next work station and to stop and fix defects as they find them. Luckily, the jig we built into station one has eliminated the majority of the defects. Even though they are not being managed and working at a slower pace, I noticed planes being completed every 24 seconds. Notice the previous two runs, there was no way to tell how often planes would exit the system. The X plane actually made it through the system in just under one minute.

Let’s review our metrics for the third run. You can see as far as space goes, they only used two tables because they were much more compact. Work in process was only three and that was controlled by the Kanban in between each station. They actually produced 16 good planes, which is nearly double what they produced by using mass-production. One hundred percent of the planes were good because of the quality at the source. Lead time was one minute. In predicatively, one minute, the X plane flowed through.

Number of people in the system was four. They ran again for five minutes. Their productivity, which is good parts divided by people divided by time is .8. You can see that even though they were working at a slower pace, by pulling and pacing, they were actually able to more than triple their productivity. They also were able to more than double the amount of good planes that they built and their quality was impeccable; 100%. This last run is optional. If you have some colored paper and some colored post-it notes, you can run this portion of the simulation. This portion of the simulation is just to show you that it can run with multiple types rather than just one single log. For this final run, we set up colored post-it notes that correspond to each of the four different plane models we’re making; red, yellow, green, and blue. An exposed red post-it lets the operator know that the final customer along the line pulled a red plane. Only the pulled color is replaced.

I also wanted to show you a U-shaped cell. This is traditionally how cells are set up. We’ll develop this further in the cell series, but workers are generally kept on the inside of cells to minimize walking between stations and to lend a helping hand when needed. Also notice that the cell can either expand or shrink depending on customer demand. If demand goes down for colored planes, this cell can run just as well with two operators as it would with four, just at a slower pace. Here’s a summary of what we’ve learned. We learned that Lean has a very long history. I started the lesson at Adam Smith but some say it even pre-dates him. The reason I started with Adam Smith and went forward is because I want to show that Lean has a long history. It’s not just a flavor of the month or something that showed up in the last five years. Next we learned that Lean was developed through a [inaudible 00:14:42] learning process throughout history. We started with Adam Smith, we had Frederick Taylor contributing, Henry Ford, Kiichiro Toyota. Each man taking the previous contributors work and developing it a little more into what we know as Lean manufacturing today. We finally learned that about 60 years ago, Toyota began to formalize all this learning and put it into a comprehensive system that we know as Lean today. Finally I want to mention that Lean has many components. It is one business philosophy. Now this is broken down into easy to understand steps on this website, but it functions as [inaudible 00:15:15] comprehensive philosophy.

One of the wastes in our agency is “Employee skills not used” and there are many high paid staff doing work that should be delegated to administrative assistants, but they cannot because their process is locked in their head, their “tribal knowledge” repository. So this underlines that processes, that reflect value-added and non-value added activity, should be visible so the right personnel can be used to the best effect.

Focusing on the last paragraph in this article:

Having used this (paper airplane) model and many variations of this learning game such as building small Lego trucks with thousands of participants, I heartily agree that this activity contributes to very positive Lean learning in many ways, often being able to inject a little humor and management humility to lighten up the learning environment. The emphasis on active participation including students sharing their thinking behind the answers they give is essential – part of the essential human development need that is often overlooked in favor of simply using the tools.

There are numerous operational aspects that you can highlight while using simple games such as this, depending on what it is that you want the key take-aways to be:

– Who is responsible for quality here – How can we stop creating or at least not pass defects as we saw in this exercise?

– How our work links to the financial performance of our company – What are the input costs and outputs of the current and trial methods and why is this improvement important to our company and customers?

– Redefining the role of shop floor management – Who is responsible for fixing these problems? How is it done today – what should we do going forward based on what we learned today? Go and See, Facts vs. Data.

Have fun!

Great game for learning Lean concepts. Cheap materials, simple instructions. Thanks for sharing.

Have you ever done a round where each worker folds the entire plane?

Hi Jason,

No I haven’t; I think that approach would miss a few learning opportunities. The assembly line approach enforces dependency, reveals constraints, encourages teamwork (or finger pointing), etc.

What are your thoughts on this? There are also variations on the same experiment – with lego blocks, etc.

Pete

I’ve done this with envelope stuffing and added the round 3 which led to discussions about cross-training, importance of skill, generalist vs specialist, when to combine responsibilities vs split them, etc.

I would use the same discussion topics for the earlier rounds so the learning opportunities shouldn’t be missed but more concepts are added in round 3.

Hello,

I have tested the game with my team, and we enjoyed it. Thanks for sharing it!

However, I feel a little bit uncomfortable with the proposed Data Collection table.

For each round, we have measured the time elapsed to complete 20 QA-accepted airplanes. Let’s say duration for round #2 is 5’10”. What can we conclude at this step? If I am right, an external observer can only conclude that the average throughput of the factory equals 3.9 airplanes per minute.

Next, given that the total WIP is 4 airplanes in my example, we can conclude that the average cycle time equals 4 / 3.9 = 1 minute by applying Little’s Law.

Therefore, the order of computation for each round would be: duration for 20 airplanes -> throughput; throughput and WIP -> CT.

However, if one read the proposed Data Collection table, from left to right, the suggested order of computation is merely: throughput -> CT; WIP and CT -> TPH.

Is there a mistake in the way I have interpreted the suggested computations?

Fantastic learning experience and applicability. We conduct workshops for adult managers

and find this exercise of immense utility.

Hi, This looks like a really good game. I’m noticing some inconsistencies in the description that are making it hard to follow though – specifically in the number of people involved and what they are doing. The above states:

Participants

4 Workers

1 Quality Assurance Worker

1 Timer Worker (person that times in seconds)

Then:

First of all, you need six total volunteers. Four will serve as workers. One will be a manager and one will be a material handler.

Then:

The lead time for the X plane was one minute. There were six people producing.

Can you please clarify exactly who is doing what, and who are the people “producing” – is that the whole team? equally is the QA worker the material handler during the game and the QA after or is it something different? Also is the manager the timer worker, therefore how is their role redundant or are they a worker as well (therefore meaning there are five people building planes)? or are they just a Manager?

Many thanks 🙂

The page has been updated, to more closely align with the videos. Thanks for pointing out the confusion. Round 1 requires 7 people (6 workers, 1 timer), Round 2 requires 7 people (4 workers, 1 manager, 1 material handler, 1 timer), and Round 3 requires 5 people (4 workers, 1 timer). Hopefully that helps. If not, let us know.