In any Lean Transformation Journey – or a corporate culture change for which lean manufacturing principles are a major part – there are many perceptions and emotions that permeate the workplace. Often, perception is reality, so it’s important that we manage the perception as well as the reality. And clearly, we must do those things that don’t “Jack Kevorkian” our lean efforts.

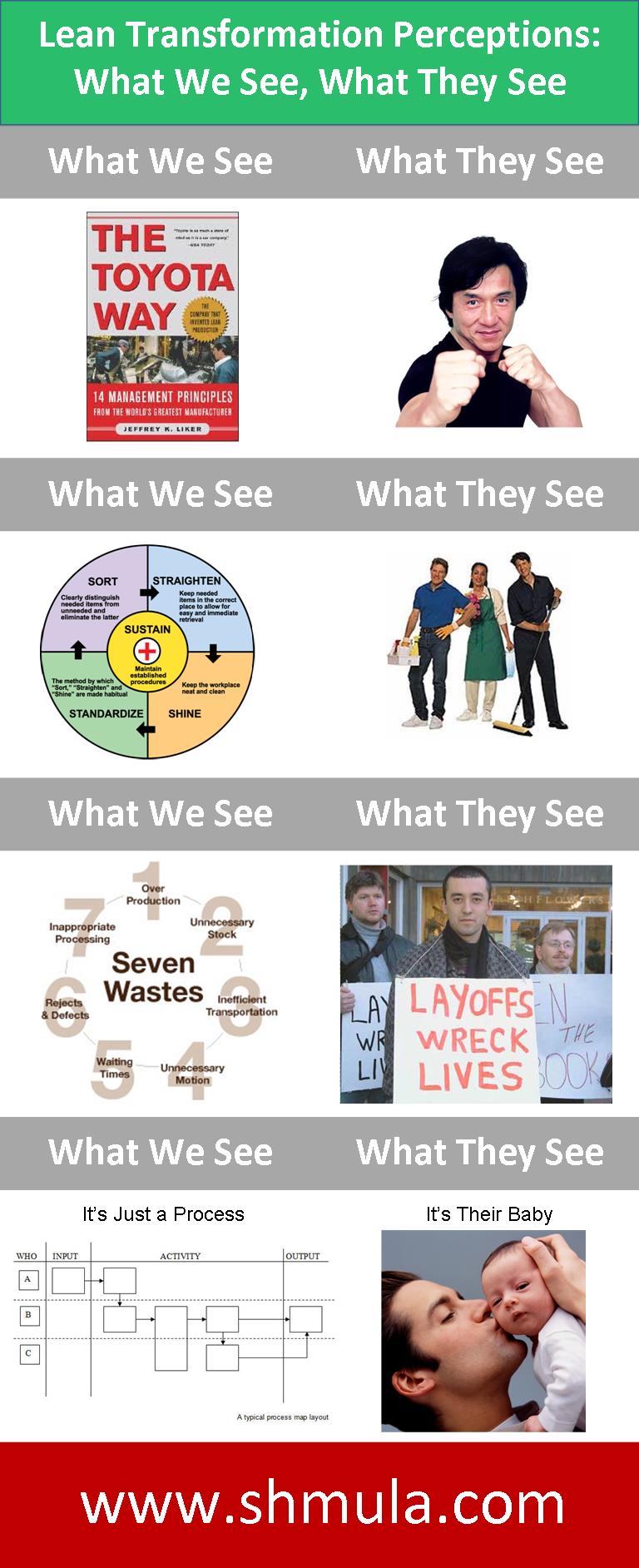

From my experience, what I show below are typical perceptions that come with a lean transformation, turnarounds, or deployment of continuous improvement or process improvement. The Infographic below also reveals stereotypes, some of which is funny, some of which needs to be dealt with in a more serious way.

Here are some examples:

- We see the Toyota Production System, they see another Japanese Quality Movement or some “Asian Thing”.

- We see 5S as a method for stabilizing a process and introducing a systematic way to remove physical waste; they see a housecleaning effort.

- We see the 7 Wastes; they see a workforce reduction or a layoff – which is not usually the case.

- We see a process to be improved or a value stream to be improved; they see the process or value stream as their baby and us calling their “baby ugly”.

Does what I show ring true from your experience? What is your lean transformation experience?

Interested in placing this Lean Transformation Infographic on your website? Use this code:

<img class="size-full wp-image-8520 aligncenter" title="lean-transformation-perception" src="https://dev.6sigma.com/wp-content/uploads/2024/09/lean-transformation-perception.jpg" alt="lean transformation-roadmap-consulting" width="610" height="1503">

True, and it is even worse when giving feed back to product developers for the products they have developed.

managementbyninjutsu.com

Excellent post and picture! 🙂

I will try to remember it when talking to management!

(I’m a Lean coach)

There are many other misperceptions, including the one propagated by the WSJ that Lean is just about Just-In-Time and inventory management.

http://www.leanblog.org/2011/05/fox-news-channel-understands-lean-better-than-the-wsj/

Some point out that LEI and “the lean community” need to do a better job of teaching, but all of the right information is out there. People need to be willing to learn, research, and get a good mentor. Too many people think Lean sounds simple and easy, so they don’t feel the need to go really learn… hence the misperceptions.