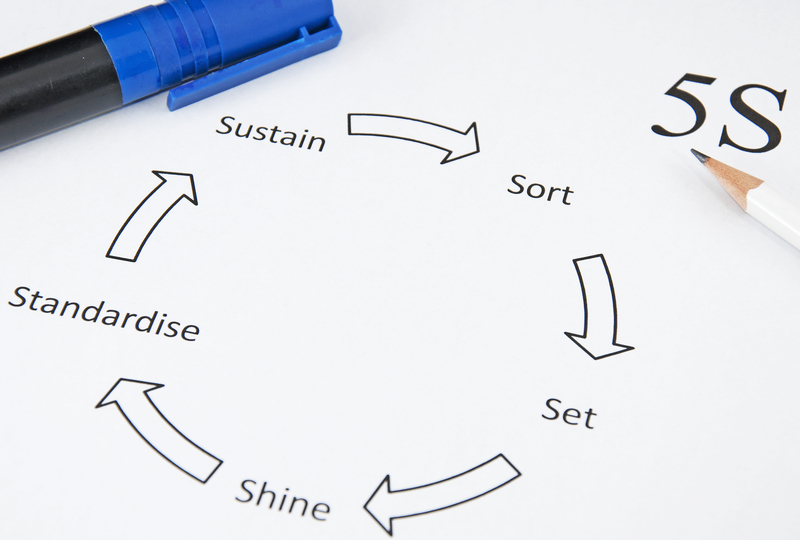

There is a war on waste, and lean principles are leading the attack. Lean is a proven methodology for the elimination of waste within a process. It is centered on making obvious what adds value by reducing everything else. The key principles that lead the battle are known as 5S. Sort, Set in order, Shine, Standardize and Sustain are the elements that are used consistently to eliminate waste. Waste is often invisible in our work environments. The traditional seven wastes are defects, inventory, processing, waiting, motion, transportation and overproduction. By applying the 5S methodology, waste can be identified and attacked, then subsequently eliminated.

Lean and Cleanliness

That is also the elemental cleaning function in an organization. When you look at the 5S principles, you will see that cleaning is firmly represented. When organizations implement lean, they go through several steps that have cleaning activities embedded. Often when 5S activities are conducted, they are focused on one area or subject matter, not the entire organization and not the overall cleaning function. One area or function might see improvement, but the overall organization might still need help.

Organizations that have embraced lean have not applied those principles to the cleaning process. Many still view cleaning as a housekeeping function, almost as a necessary evil. There is not enough focus applied, shortcuts are taken, and the overall organization suffers. The focus might be on getting by as cheaply as possible, unaware of the waste that is being created, which far outpaces any dollars saved on the front end. The same is true for a manufacturing plant, office or any other work environment, or even your home. The longer you wait to make needed repairs and improvements, the more expensive it will be in the long run. And, the longer you take to maintain something properly, the faster it will deteriorate.

No responses / comments so far.