I had an opportunity to visit a local Jiffy Lube for an oil change recently. I needed to change the oil in our car before moving to Tennessee. In the process of getting an oil change, I learned how Jiffy Lube approaches work and their adherence to metrics. You can also view all 40+ articles on Queueing Theory.

This Jiffy Lube had 4 bays and at the time I was there, 3 were occupied.

PS: Read this article you’re interested in learning about the role of the Jiffy Lube Waiting Room Bay Window.

While my car was waiting, I had a good conversation with the shift supervisor at Jiffy Lube. I asked him about their approach to work and how they hold themselves accountable. Here is what I learned:

- Instead of dividing up his team and have a few work on each car, he has the whole team work on 1 car at a time. Without knowing it, he was applying the principle of single-piece flow. And then I asked him why not divide up your team and work on all 3 cars at the same time. He said something profound and very pragmatic:

“It’s just faster to work on one car at a time. We get ‘er done that much quicker.”

- They religiously keep track of time the second the car enters the bay until the car exits the bay. This supervisor said they monitor how they do per week and have a daily standup every morning to discuss how the previous day went. In that meeting, they go through some simple problem solving on how to go faster that day. Again, without knowing it, this team is applying some level of PDCA.

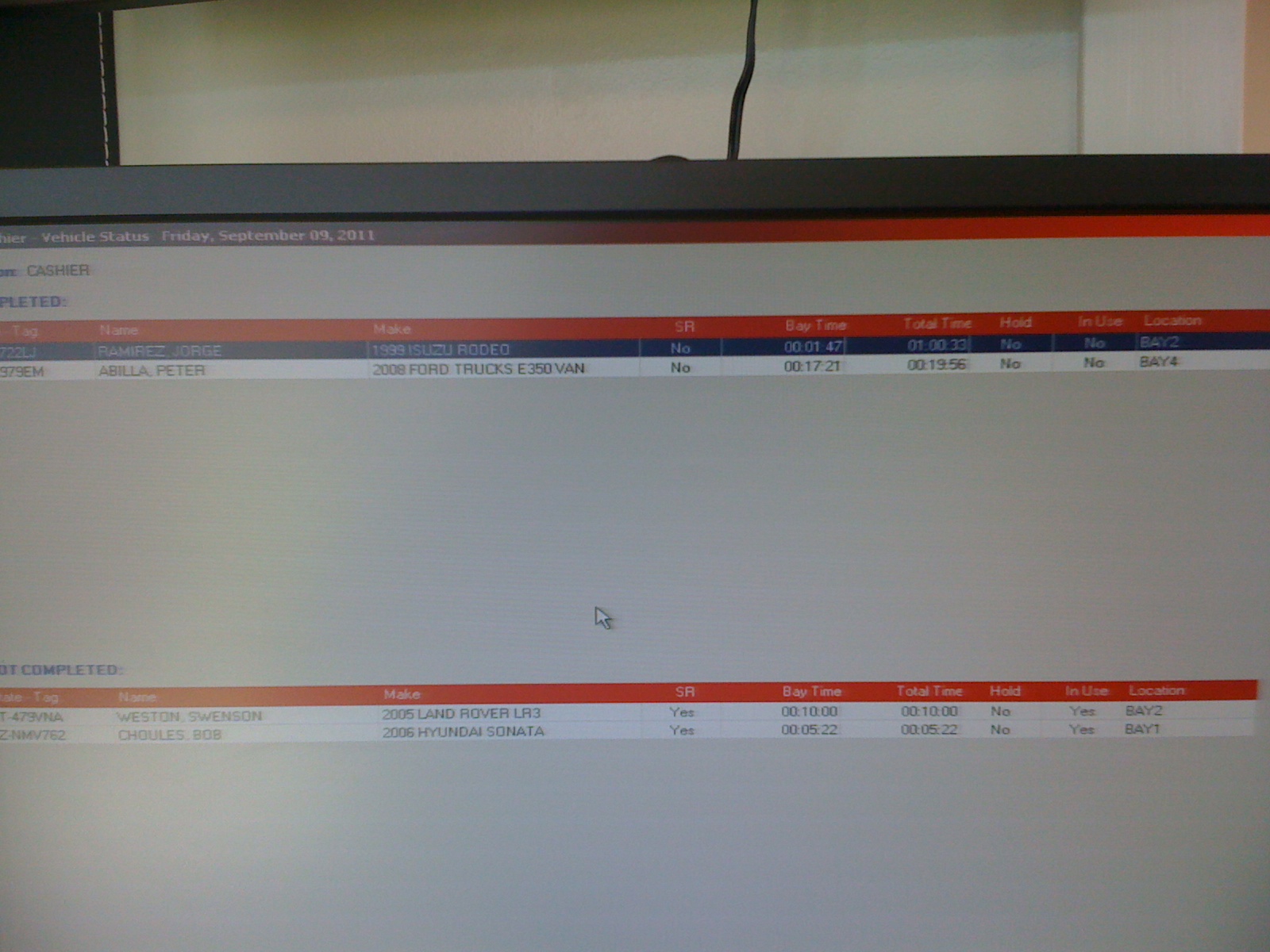

- For this team, it’s not good enough to track time based data internally, they publish it in a large screen in the waiting room. As the picture below shows, my van was in Bay 4 and was in the Bay for 17:21 minutes and a total time of 19:56 minutes. It begs the question, though, why the Isuzo in Bay 2 was in the bay for just a few minutes but was there for 1 hour. Interesting.

Additionally, without knowing it, this supervisor – or this Jiffy Lube for that matter – was applying some other best practices for how to manage queues, such as the application of one piece flow I explained earlier. It’s great to see effective and practical applications of Lean and Queueing.

Have you seen any lately? Share your thoughts here.

No responses / comments so far.