5S Lean Manufacturing Download

Instant Download FREE – Guide will be Sent To your Email Address.

Brands you love trust Shmula.com Lean Six Sigma Training Materials

5S is considered a first step to applying Lean. In this FREE 41 slide PowerPoint Presentation you’ll learn the following:

Lean Manufacturing and Six Sigma over the years have come together and are both being applied by many companies to processes from manufacturing to service operations to healthcare. In this 41 slide PowerPoint Presentation, you will learn why 5S is a fundamental aspect found in both Lean and Six Sigma.

I’ve never understood why most organizations start their Lean journey with 5S. Most consultants advocate this approach also. I take a different view.

In an earlier post, Jamie Flinchbaugh argues that organizations shouldn’t begin their Lean journey with 5S for the following reasons:

- If your first step in Lean is one that involves mandates, it is harder to get long-term engagement.

- The benefits of 5S are long-term and not direct.

- 5S doesn’t force engagement of executives or senior management.

In a follow-up post, Jon Miller responds and, mostly agrees, but makes this point:

Even if discipline through 5S is not the first and most urgent behavior change, don’t let that delay you for very long in doing 5S. There are reasons that 5S is a building block and prerequisite of so many other aspects of lean … And when invited to visit your workplace, I will never accept “Discipline is not the most urgent behavior we are trying to change” as an excuse for trash on the floor, cluttered workstations or any other signs of poor 5S.

Before I respond, let me quickly explain what 5S is:

What is 5S?

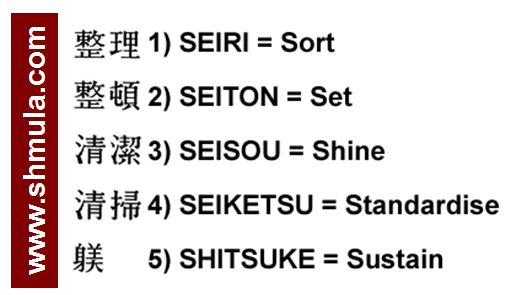

Each of the “S” in 5S means the following:

- Sort. Clearly distinguish what is necessary to do the job from what is not. Eliminate the unnecessary.

- Set in order. Put needed items in their correct place to allow for easy accessibility and retrieval.

- Shine. Keep the workplace clean and clear of clutter. This promotes safety as well as efficiency.

- Standardized cleanup. Develop an approach to maintaining a clean and orderly work environment that works.

- Sustain. Make a habit of maintaining your workplace.

Or, here’s a simple image of the above definition of 5S:

Why You Shouldn’t Begin Lean with 5S

I agree with both Jamie and John. But, my reason for not beginning with your Lean journey with 5S is simple:

Start your Lean journey with what the organization needs most. In other words, it depends.

For example, if the organization is a Healthcare facility, such as a hospital, then beginning your Lean journey with 5S is very important, because organization, safety, and visual management are very important in reducing or eliminating medical errors.

But, if the organization is a call center, then 5S becomes less important. In that environment, the big question is “why are inbound contacts happening at all?”

True, 5S as a support program for an overall Lean journey in a call center can be helpful. But, it’s a very minor part. The key question keeping call center executives up at night is this: what can we do to improve the customer experience AND reduce inbound product warranty contacts? Rarely will 5S help in answering that question.

Or, if the organization is primarily a software organization, then elements of 5S are important, but not all. For example, Kanban for software development is gaining popularity, with the support of 4S: Sort, Set in Order, Standardize (standardise), Sustain. Visual Management is a key component in these software organizations.

In short, it depends.

I disagree with Jamie’s point (3) above. In fact, I believe that most consultants encourage their client companies to begin their Lean journey with 5S because the effects are so immediately visible – there’s nothing that emotionally lifts team morale more than to see before/after pictures of a workplace after 5S. But, the problem with most consultants is that they only do the first 3 steps of 5S and then they leave. The client company loses out since, arguably, the most important steps of 5S are actually the last two: Standardize and Sustain (Self-Discipline).

The most important steps of 5S are actually the last two: Standardize and Sustain (Self-Discipline).

I will say this: Lean will not be adopted and championed by senior management unless it can be demonstrated that the principles and practices of Lean impact the key metrics for which the senior management is accountable. And, rarely will those metrics be the metrics that 5S are meant to influence (except for safety).

Download the free training packet below!

Pete,

In your conclusion, when you talk about the “key metrics … for which senior management is held accountable”, it sounds like you are saying “ride the management wave, not the black belt board.” The difficulties that most Lean journey’s face is a burden of proof in challenging any one of those cherished key metrics. I am afraid that this is the reason for “it depends,” and an explanation for why safety is one of the more direct and easier connections into senior management circles.

tony

Pete,

In general, I agree with your point. However, what about 5S for information? When you look at a non-manufacturing environment, the waste of waiting and motion is often caused by poor information 5S — people can’t find what they need, or important information isn’t addressed in a timely fashion. (Think of the Mars Climate Orbiter explosion, which could have been avoided by not having the email get lost in the program director’s inbox.)

Pete, thanks for the reference back to my post.

To you counterpoint on my point #3, it would help if I were more specific about what I mean by engagement. I agree with you that it can generate interest and even excitement in management because of it’s very visible nature. By engagement though, I mean that management changes their work as well. Besides auditing other people’s work, 5S doesn’t do much to change the work of management in any meaningful way. This can lead to a mental model that lean can be delegated, when in fact it cannot.

Thanks,

Jamie Flinchbaugh

http://www.jamieflinchbaugh.com

RE 5S. An added thought about introducing 5S. At the heart of 5S is a better way to carry out tasks. If the benefit to the operator is stressed and understood over “clean,organized” then using 5S as a grounds up starting point for Lean makes sense. Your blog subliminally poses an either or situation – either start with 5S or start where the pain is. In my practice over 12 years I have found that often, but not always, 5S plus pain reduction are perfect matches to educate the wider employee population.