Process behavior charts or control charts were invented by Walter Stewart in the 1920s. They are a great statistical tool that analyzes how a process changes over a period of time. His main aim of inventing them was to reduce variation in the manufacturing process. If this sounds confusing right now, don’t worry. This brief guide will explain what a process behavior chart is, along with its most important elements.

What is a Process Behavior Chart?

Simply put, a process behavior chart is a graph that is used to display changes in the output of a particular process over a period of time (time sequence).

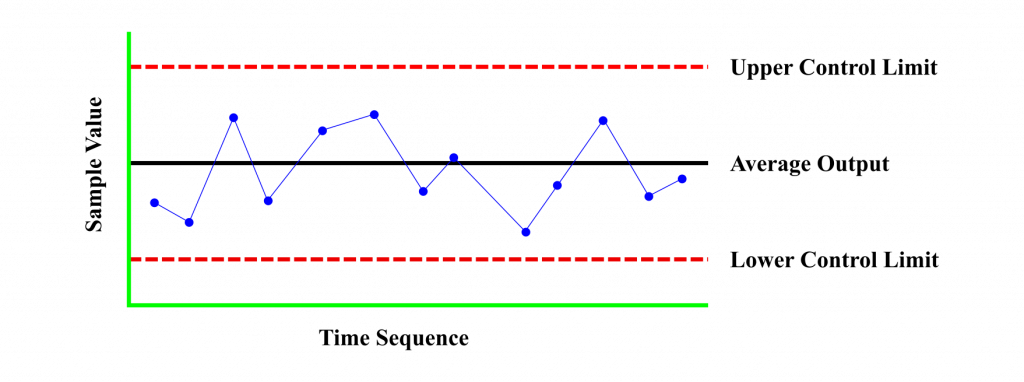

Take a look at the figure below for an example of a typical process behavior chart.

As you can see, a process chart has some important elements that give one information about the process in question. We have a center line (average output), the upper control limit (UCL) and the lower control limit (LCL). The blue line and points represent the actual output of the process and the variation between them. These lines are drawn using historical data. And by looking at the chart, we can tell whether the variation of that particular process is predictable or unpredictable.

We will discuss the elements of the chart in a little more detail below, starting with the most important one: variation.

Variation

You have heard the concept of variation being mentioned a lot, but what is it exactly? Basically, variation is a number that is indicative of the level of variance between each member of a particular group. In the figure above, the blue line between each point displays the level of variation between outputs in a process.

If you analyze each piece of data that has been measured in the real world, you will discover some degree of variation. No matter how hard we try, we can never obtain the exact same results when it comes to any process. Each result will be unique in its own right.

While a little variation is not a big deal, too much of it can be troubling. This brings us to the two types of variations that can be observed in a control chart: common cause variation and special cause variation.

A process that is stable and in control will produce common cause variation, meaning it is predictable. This type of variation is inherent in the process, which means it is expected from its normal operation, and there’s nothing you or anyone can do about it. Special cause variation happens when the process displays unexpected variation resulting from unknown external factors.

You can tell there is common cause variation at play when points fall outside the control limits. This indicates that the process is in trouble. Reducing this type of variation is crucial to keeping the process stable and in control.

The Center Line

As you can see from the figure above, there is a solid black line in the middle of the control limits. This is the average output or center line, and it represents the output you will get from the process on average. It is used to compare how the process performs compared to the average. When the process in control, the points around this line will vary randomly.

Control Limits

By looking at the random variation occurring in the process, you can work out the control limits of the process (red dotted lines). You have the upper control limits and lower control limits, and the performance of the process must not go beyond them if the process is to remain in control. There’s also what is known as specification limits. But these are determined by the requirements of the process, which are then determined by the client, rather than its variation.

So there you have it; a brief look at what process behavior charts are. They are an important tool used by organizations that utilize Lean and Six Sigma methodologies, especially in the manufacturing industry. They offer them a powerful way to analyze the performance of a process, allowing them to make informed decisions, especially when it comes to its improvement.

No responses / comments so far.